Automated container inspection

A packaging manufacturer were looking for an automated way to test and inspect plastic containers.

Challenge

Our customer, a packaging designer and manufacturer, required an automated system that could test and inspect plastic bottles.

The tests that needed to be carried out included measuring various parts of the bottle, testing the amount of liquid the bottles can hold, as well as the amount of force the top of the bottles can take.

Invention

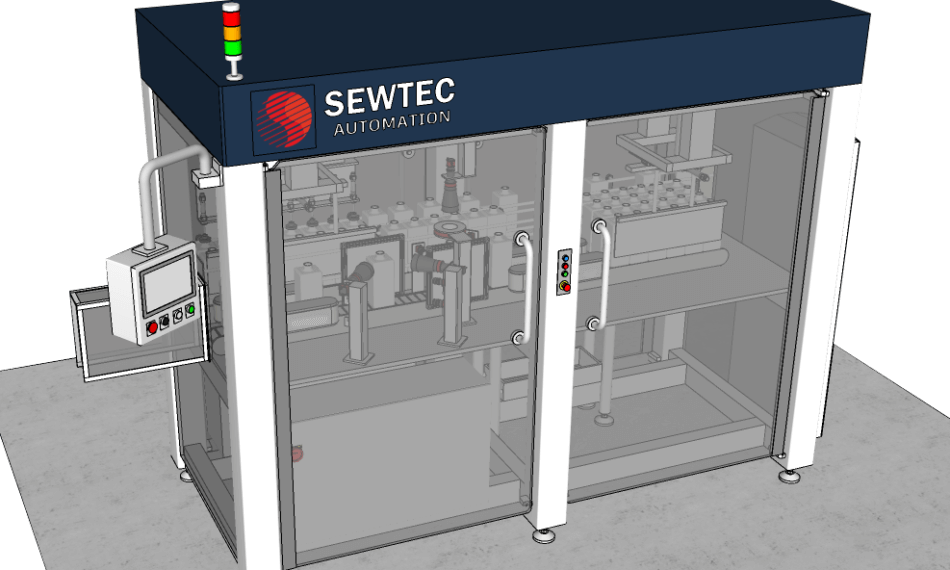

Sewtec designed a solution that incorporated the required testing modules all into one complete integrated system.

The containers are fed into the inspection machine via a conveyor to a six-axis pick and place robot that transfers the bottles between each inspection module.

A single bottle enters the machine and is placed into a rotary table by the robot where the external dimensions are measured using a high resolution vision system.

A pair of digital contact probes then measure the internal diameter and the bottle is transferred to the next module.

A non-contact measurement sensor checks the thickness of the bottle at pre-set positions.

The vertical strength of the bottle is tested via a motor driven slide that applies force to the top of the bottle.

The final module of the inspection system weighs the empty bottle then fills it with water to calculate volume capacity.

Results

The automated quality control system for our customer processes batches of 20 bottles at a time and also has the ability to increase this amount depending on the diameter of the bottles tested.

The solution was designed, built and installed by Sewtec, offering our customer a single source supplier to handle the project from start to finish.

Our customer also receives through-life support for this system. This covers spares, regular maintenance, and controls upgrades to ensure the solutions remains effective throughout its operational life.