Case Erector – End Feed

Automated case erector, designed to suit a wide range of products. Fast and easy changeover with precise case forming to ensure square cases and class leading production efficiencies. A stand-alone machine with integral control system, fully guarded and compliant to ensure safe operation.

| Throughput speed | Up to 20 cases per minute |

|---|---|

| Closure type | Tape, glue, or tape & glue |

| Safety | Compliant with PL-d as standard |

| Warranty | Standard 1 year (with upgrade/extension options available via Sewtec Care) |

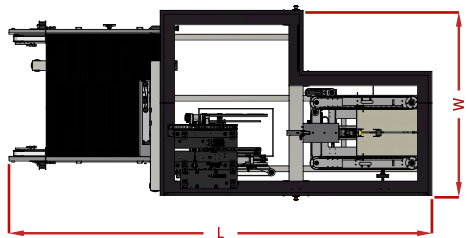

Layout

Dimensions shown in table below. Layout represents large machine. Multiple layouts and machine handing options available.

Options

Technical Data

| Small machine | Large machine | |

| Machine Dimensions | L 3785mm / W 1400mm | L 4435mm / W 1940mm |

| Throughput speed | Up to 20 cases per minute | Up to 20 cases per minute |

| Case size minimum | L 200mm / W 150mm / H 150mm (top flaps open) | L 350mm / W 250mm / H 300mm (top flaps open) |

| Case size maximum | L 500mm / W 400mm / H 600mm (top flaps open) | L 780mm / W 500mm / H 870mm (top flaps open) |

| Magazine infeed width | 1000mm | 1280mm |

| Seal type | Tape, glue, or tape & glue | |

| Load height | 550mm | |

| Outfeed height | 600mm +/- 60mm | |

| Electrical | 400V 50Hz Neutral. Other voltages may incur additional costs | |

| Air supply | 6 bar compressed. Constant feed pressure / flow rate | |

| Control system | PLC and HMI with tri colour status beacon, counters and scales in metric | |

| Machine finish | Powder coat RAL9001 and RAL5011. Alternative RAL colours and stainless steel options available | |

| CE | Machinery fully CE compliant | |