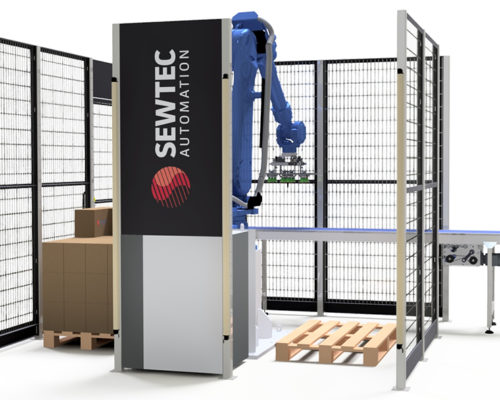

Palletising system

Automated system to stack cases onto pallets utilising a 5 axis robot. Complete with pallet de-stacking unit with integrated infeed and outfeed system. Embedded pallet configuration tool, accessible from the HMI for ease of use and recipe control. A stand-alone machine with integral control system, fully guarded and compliant to ensure safe operation.

| Pallet configuration | HMI recipe driven |

|---|---|

| Pallet size (mm) | CHEP (1200 x 1000) or Euro (1200 x 800) as standard |

| Safety | Compliant with PL-d as standard |

| Warranty | Standard 1 year (with upgrade/extension options available via Sewtec Care) |

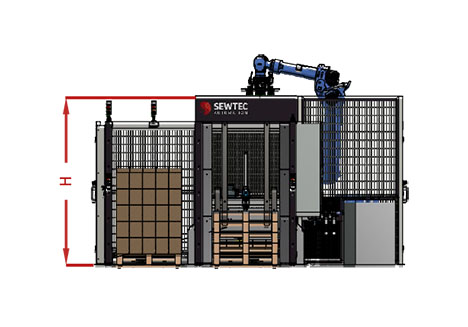

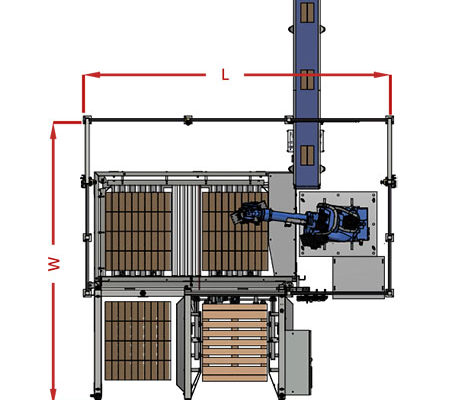

Layout

Dimensions shown in table below.

Options

Technical Data

| Machine dimensions | L 4800mm / W 4440mm / H 2610mm |

| Pallet size | To suit CHEP or Euro pallets as standard. Other pallet sizes available on request |

| Pallet de-stacker capacity | Up to 15 pallet stack capacity |

| Electrical | 400V 50Hz Neutral. Other voltages may incur additional costs |

| Air supply | 6 bar compressed. Constant feed pressure / flow rate |

| Control system | PLC and HMI with tri colour status beacon, counters and scales in metric |

| Machine finish | Powder coat RAL9001 and RAL5011. Alternative RAL colours available |

| CE | Machinery fully CE compliant |