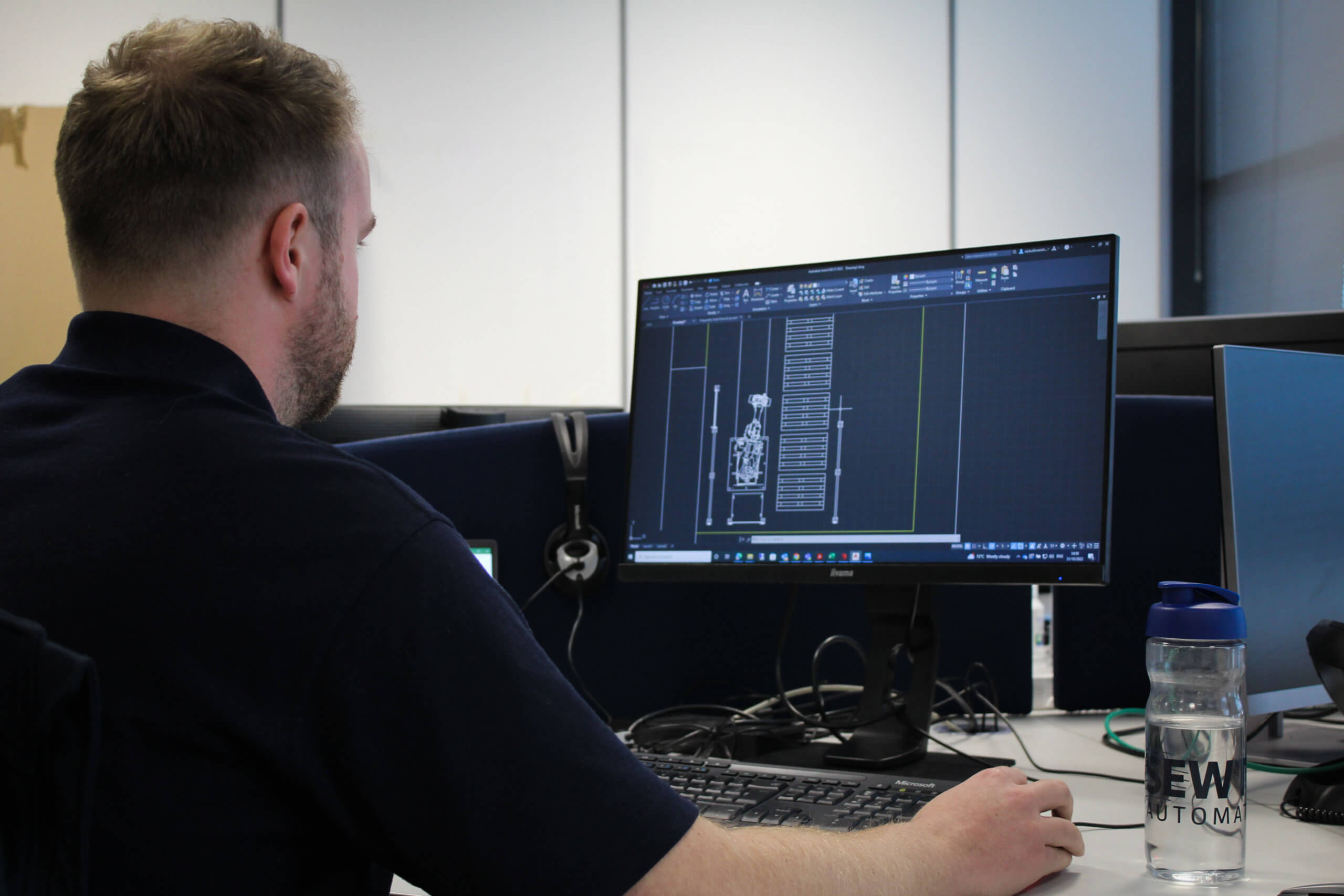

Ed Bulliment, Applications Engineer

We are very proud of the talent we attract here at Sewtec. Every member of our team inspires creativity and passion in the work they do every day.

In our latest ‘day in the life’ series, we caught up with Ed Bulliment, one of our applications engineers, who walks us through what it’s like working at Sewtec and what the future has to offer.

Q: Tell us about your typical working day

EB: Every morning starts with the applications technical review meeting, where the apps and sales team meet to discuss current enquiries. The technical, controls and sales director all take part in this meeting, so it’s a great time to run through technical obstacles to ensure we are offering the best solutions to our customers.

The main function of my role is to develop system concepts, calculate costings and work with the salesperson to bring the customer quotation together. Every enquiry has its own bespoke solution; some solutions will be based on systems we have built in the past, and others will be based on any number of our standard machines. There are also enquiries where we start with a blank canvas. I am involved with the full range of costing jobs, so my days vary with each job. However, most of my days will involve working on CAD, Excel, Project and Teams along with working collaboratively with colleagues from the different departments and suppliers.

Q: What made you choose a career in industrial automation?

EB: From a young age I have enjoyed building things and being hands-on. At school I excelled in maths and physics, and to top it off my dad is also an engineer, so a career in engineering made a lot of sense. I studied mechanical engineering at university and took part in industry placements in engineering companies. From these experiences, I identified that I wanted to work in an industry that was fast paced and offered lots of variety. After some research I decided that I liked the look of the food/packaging industry.

I then worked as a project engineer for a contract packing company, lots of variety and very fast paced! I was responsible for managing a wide range of packaging machinery installation projects. Contract packing traditionally uses a lot of labour and therefore there are great opportunities to automate processes. Out of all the projects I was involved with, I enjoyed the automation projects the most, and I particularly enjoyed working closely with suppliers on solutions that required a bespoke approach. Being involved with the design of such systems made me realise a passion for automation that drove me to seek a job for a company that specialised in building bespoke machinery.

Q: What would you say the best thing about working at Sewtec is?

EB: The range of projects we are involved in means that every job is different. I thought I had been involved in a wide range of projects before joining Sewtec, but we are involved in such a vast array of projects, I feel like I learn about a new or different application every week! I really enjoy working for a company that takes on the complex challenges that many other companies would shy away from. We love a challenge, and we are great at what we do.

Q: Name three characteristics you would say are needed to work as an application engineer?

EB: Communication – gathering the correct information is crucial to ensure we meet the customer needs. It is also important that I can explain complex systems to colleagues, suppliers, and customers with aid of visuals that are clear for people from all backgrounds.

Problem solving – being presented with a problem is something that happens with the majority of the customer enquiries we see. That’s why they come to us, if they could solve the problem themselves, they would. So being able to break down a problem into its individual components and coming up with solutions is critical to the applications role.

Receptive – The best solutions are those that have been worked on collaboratively, so when presenting your own concept solutions to colleagues or customers it is important to encourage feedback and to consider new suggestions and ideas.

Q: What has been your proudest moment whilst working at Sewtec?

EB: From the day I started, I have felt proud to say I work at Sewtec. There are times where I feel especially proud, such as showing customers or suppliers around our facility or representing Sewtec on customer site visits.

Q: How have you developed your skills whilst working at Sewtec?

EB: Working at Sewtec has developed my overall automation industry and engineering knowledge. There are people at Sewtec that have worked in the industry for over 30 years, and I enjoy absorbing as much of their knowledge as I can. An area of knowledge that I have developed significantly since joining Sewtec is the use of robotics in automation. In previous roles I have had limited exposure to robots. At Sewtec, we have a good relationship with many robotics suppliers, and I have visited several of their sites to better understand their range and capabilities.

Q: What aspirations do you have for your career at Sewtec moving forward?

EB: Sewtec have an ambitious vision and I’m excited to see how the company grows and what opportunities there will be for me in the future. My focus for now is developing my own skills and my understanding of the wider business. Sewtec have been very supportive of this and have actively encouraged me to fill in any knowledge gaps by spending time with different suppliers or colleagues. I have also been involved with some active projects which has allowed me to see how other departments operate. I aspire to become as experienced and proficient as those colleagues I have been able to learn from in my first year at Sewtec.

If you like the sound of working at Sewtec, visit our Careers Page for more details on our current vacancies.