Integrated industrial automation and robotics

Across production lines the need for industrial robots is key, and our industrial automation and robotics systems can support this. From picking and placing products to undertaking packaging operations, utilising robotic functions improves efficiency and increases productivity across all sectors.

Inventive industrial robotic automation by Sewtec Automation

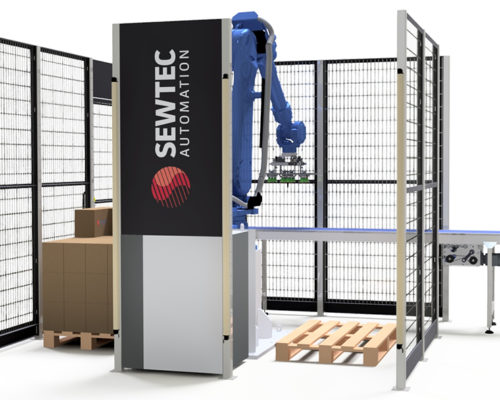

Sewtec Automation is a turnkey solutions provider when it comes to inventing, designing, manufacturing, installing, and supporting industrial automation & robotics systems. Our systems can enhance your Overall Equipment Effectiveness (OEE), which improves both production rates and quality.

Our in-house expert team can develop robotic systems to meet your product requirements. Our automated systems can handle varying payloads, dimensions, and orientations, whilst also having differing degrees of flexibility to suit production processes.

All of our robots use industry-standard parts to simplify service and maintenance, including control devices from Rockwell, Siemens, and Beckhoff, as well as servo drives from Kinematics and Simmotion.

We also have extensive experience working with leading third-party industrial robot suppliers and regularly work with our customers to create a custom-built, integrated solution to suit their needs.

Efficient elements for industrial robotic automation

To ensure your production line operates to your requirements, we build flexible industrial robotics systems which can handle varying products, speeds, and payloads.

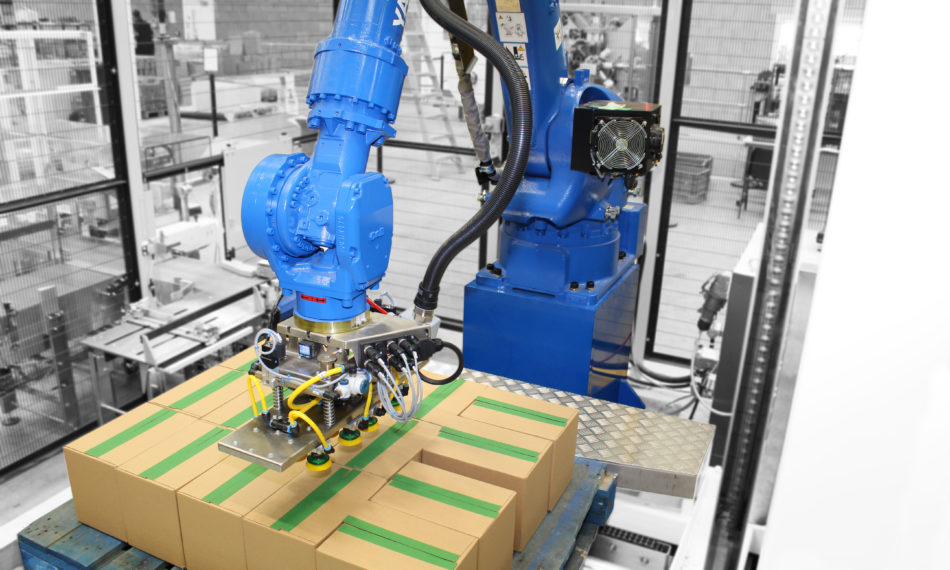

For high-speeds, heavy payloads, and flexible capabilities, we integrate our proprietary 5 and 6 axis robotic arm integration to enhance the performance of production lines.

We build industrial robotic automation systems which utilise delta robot picking systems to enable high-speed pick and place tasks to be completed.

To efficiently pick and place products across the production line, we implement SCARA robotic arms to handle items.

Our in-house-built robots are available in four different types of 2-axis system with a maximum payload of 50kg and cycle time of 104 seconds. We also offer 3 and 4-axis systems of varying weight capacity and performance.

To operate with your motion solution racetrack, we design robotic systems and software which will integrate with, and enhance, your production.

We design robotic systems that can integrate and operate with varying vision systems, which have been developed by industry leading providers.

To guarantee high speed, precision, and accuracy, our robotic solutions use drivers and motors designed to meet your production line requirements.

To ensure you products are picked up by our robots correctly, we design unique end effectors to meet your requirements.

To ensure your robotic automation system meets your requirements, we undertake simulations to prove both the cycle times and sequencing.

Our pre-designed polycarbonate guards ensure all components of a line are protected, while preserving the safety of the operator.

Our experience in industrial robotics automation

Sewtec Automation has extensive experience in creating industrial automation and robotic systems to help improve operational efficiencies.

Find out more about the turnkey solutions we’ve built by reading this case study on an automated transit packaging machine.