Bottle Inspection Machine

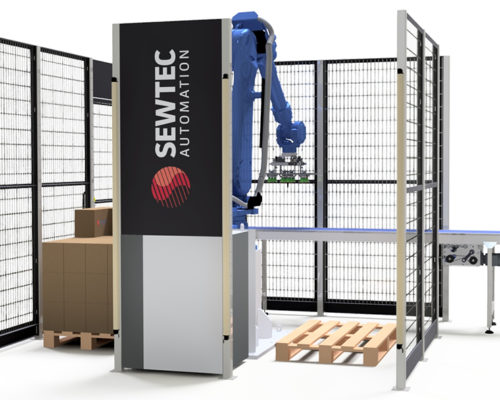

A fully automated bottle inspection and measurement machine, suitable for product batch and laboratory testing. A stand-alone machine with an open source integral control system, fully guarded and compliant to ensure safe operation. Designed and developed by Sewtec to ensure accurate and reliable product inspection and handling.

| Profile Inspection | Keyence TM-X 5000 accurate to +/- 2.4 micron |

|---|---|

| Wall Thickness | Keyence CL-3000 accurate to +/- 1 micron |

| Volumetric Test | Sewtec +/- 1ml |

| Top Load Test | Sewtec Linear Servo |

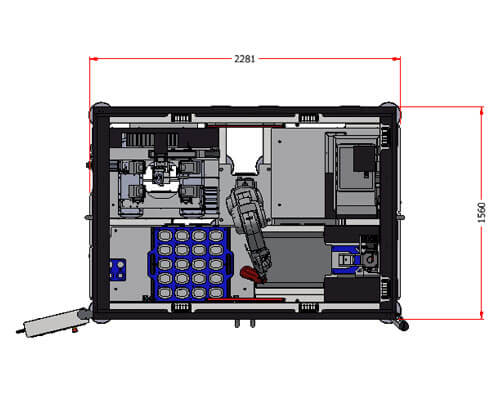

Layout

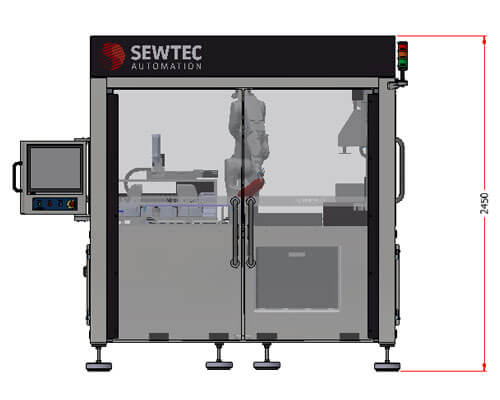

Dimensions shown in the table below. Layout may change on application

Options

Technical Data

| Machine dimensions | L 2281mm / W 1560mm | |

| Throughput speed | 1 bottle per minute depending on inspection criteria | |

| Bottle size minimum | Approx 400ml, other bottle size options available | |

| Bottle size maximum | Approx 1500ml, other bottle size options available | |

| Bottle Type | PET and PET pre form, other bottle types and material options available | |

| Load Height | Approx 1200mm | |

| Electrical | 400V 50Hz Neutral. Other voltages may incur additional costs | |

| Control system | Beckhoff PLC and HMI with counters and scales in metrics | |

| Machine finish | Powder coat RAL9001 & RAL5011. Alternative RAL colours and stainless steel options available | |

| CE | Machinery fully CE compliant | |