Cosmetic and personal care product automation

Manufacturers in the cosmetics and personal care industries produce a wide range of products in high volumes. When a product’s appearance is just as important as its function, items such as lipsticks, shampoos, razors and moisturisers need to be manufactured at high speeds, and with the utmost care.

From cosmetic filling and packaging to component assembly, every process needs to ensure the final product meets these industries’ stringent quality standards.

Specialist support from Sewtec Automation

Sewtec Automation invents, designs, manufactures, installs, and supports specialist automation solutions for the personal care and cosmetics sectors. By helping you automate essential processes such as assembly and packing lines, we can enhance the production rate and quality of your manufacturing facility.

We have a wealth of experience in delivering turnkey automated systems for manufacturers of cosmetic and personal care products. As a complete line integrator, we can maximise the Overall Equipment Effectiveness (OEE) of even the most complex of manufacturing processes.

Our in-house industrial automation capabilities enable us to offer you the peace of mind that comes with years of experience working with blue-chip global brands. Our team of experts will not only help you to transform your manufacturing processes, but also remain on-hand to offer support and advice on your systems over their full lifespan.

Our extensive serialisation experience allows us to ensure your cosmetics and personal care automation systems aid your compliance with essential regulations. The EU Cosmetics Regulation ((EC) No. 1223/2009) requires all cosmetic products supplied to the European market to meet Good Manufacturing Practices (GMP), and the Center for Research in Perspective Technologies (CRPT) aims to guarantee traceability of all products sold in Russia.

High-speed personal care and cosmetics automation

With such a broad range of products manufactured by the personal care and cosmetics industries, our automation systems are designed to support and improve a variety of core processes.

From the primary packaging used to enclose your makeup or hair care product, to the secondary packaging designed to make it retail-ready, our turnkey packaging lines help you to maximise production rates without compromising quality.

From skin care to hair care and plant-based cosmetics, your product needs to be handled delicately to preserve its appearance for retailers. Our product handling capabilities ensure your assembly lines and packaging machines can maintain the quality of your product throughout production.

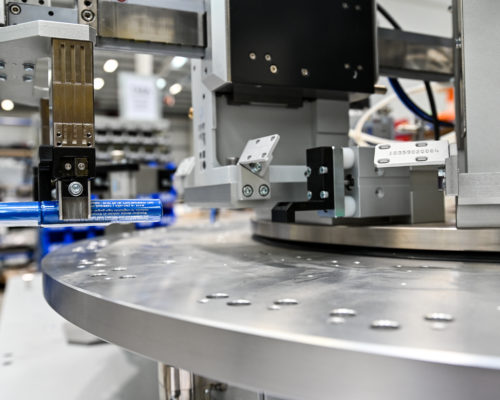

During manufacturing, products such as razors, applicators, and lipsticks require the assembly of multiple components. Accurate and delicate product assembly is critical to personal care manufacturing and our systems can help you to automate even the most intricate of processes.

Personal care and cosmetics products need to be correctly labelled to enable supply chain traceability. Our high-speed labelling lines ensure your products are carefully and correctly labelled prior to despatch.

When it comes to cutting product components, precision and accuracy are essential. We offer a variety of different cutting technologies to ensure even the toughest of materials can be cut to size.

The materials used for razor blades in the personal care industry are generally hardened to increase sharpness and durability. Our manufacturing lines use hardening technology to heat, cool, and temper the raw material.

Our track and trace systems ensure your product can be traced back to a specific link in the supply chain. The fast and accurate application of UDI codes helps the product return and recall process.

Our R&D team can act as an extension of your product development department by advising you on how suitable the design of your product is for process automation. From component design to the assembly process, we can help you optimise any of your processes.

Personal care and cosmetics automation case studies

Our in-house capabilities enable us to work in partnership with you on your next personal care or cosmetics automation project.

Find out more about our experience in developing a range of systems by reading this case study on an automated assembly machine delivering 300 ppm.