Challenge

Our customer, a product manufacturer and supplier to the medical device industry, required a new automated assembly machine to accommodate its sales growth and order fulfilment.

On consultation with the customer, Sewtec’s engineering team learned of a need for a system that could support 1,000 ppm at any given time, for around-the-clock production.

Invention

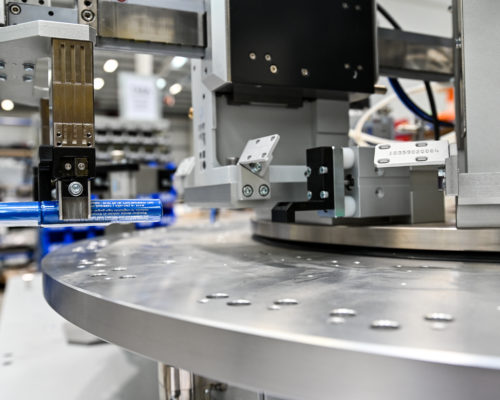

Our proposed solution incorporated a linear motor transport system to manipulate the many products necessary for the assembly, part feeders for separation, and orienteering of the various components, and our standard Servo controlled units for assembly and test. In operation, the system uses multilane technology to accommodate the many components needed per product.

Results

The new automated medical device assembly machine enables the manufacturer’s production line to:

- Run at 50 cycles per minute with each step processing 40 products at a time.

- Adhere to the requirements of the ISO8 clean room it was installed within, thanks to validation by Sewtec engineers up to the IQ phase.