Challenge

Our customer, a market-leader in the confectionery industry, was looking to source a machine to replace an ageing, highly inefficient, manually-managed repacking line.

Sewtec was engaged to ‘solutioneer’ a new system that could pack multiple items at high speeds, through a more simplified repackaging process.

Invention

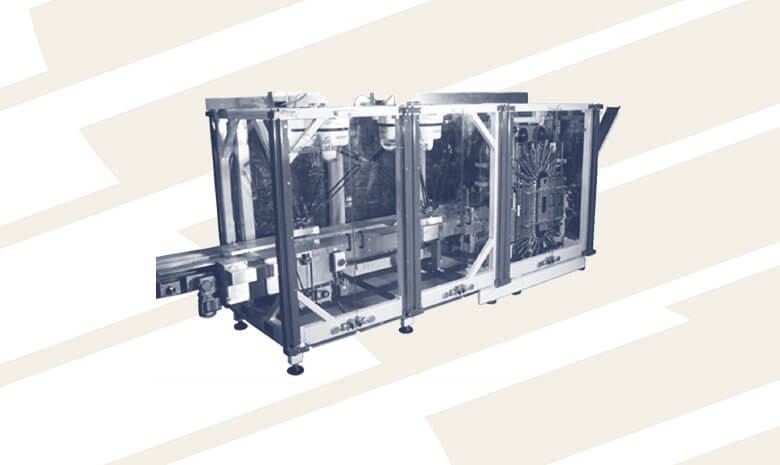

After the initial consultation when our customer’s primary objectives and the machine’s functionality and technical requirements were all considered, the Sewtec engineering team designed and proposed an automated secondary packaging solution. Our system consisted of a buffer store to accommodate material changes and a Delta robot to feed products at high speeds to an existing third-party flow-wrap system.

Results

In operation, each product arrives at the automated confectionery packaging machine from two separate production lines at 60 and 80 ppm input speeds. The custom buffer store balances the flow from both production legs and then outputs each product to the loading robots. Products are picked using custom vacuum grippers, then stacked in different formats – according to their pre-selection on the HMI – and fed to the flow-wrap system.