Challenge

Our customer, a global market leader in the tobacco industry, needed a secondary packaging solution to meet an increasingly high demand for its products worldwide.

Invention

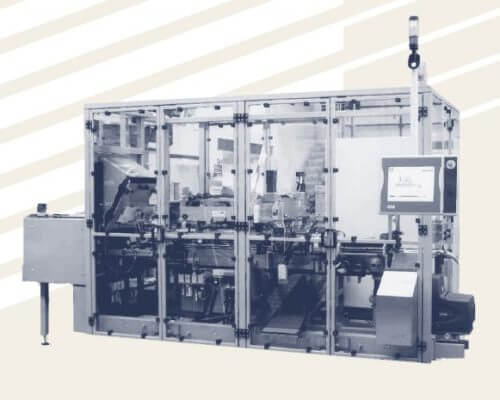

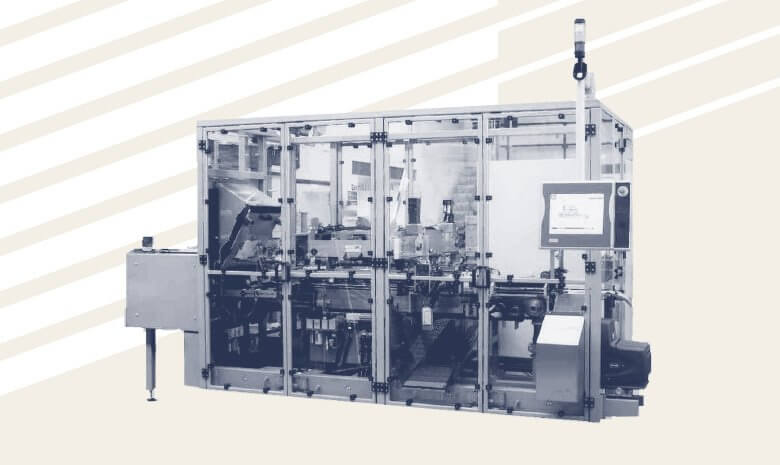

The Sewtec engineering team designed and developed a bespoke automated case packing machine that would collate and package different types of tobacco products in high volumes, using an indexing racetrack system for efficiency.

The system erects cartons from flat and uses a flexible Servo pusher to fill each one with products. Each Shelf Ready Packaging (SRP) carton features a pop-up marketing banner, also incorporated into the carton lid’s design, and is folded and ticked before it exits the machine. Crucially, the machine can operate without the need for changeover tools.

Results

The automated tobacco packaging machine supports many different types of packaging and can process products arriving at a speed of 120 ppm. Multiple versions of the machine are now deployed globally.